Newsroom

Pulp fact: How enzyme tech could lead to better paper, textile products

Reported by Silvia Moreno-Garcia, with content added by Guillaume Dejean, Brumer lab

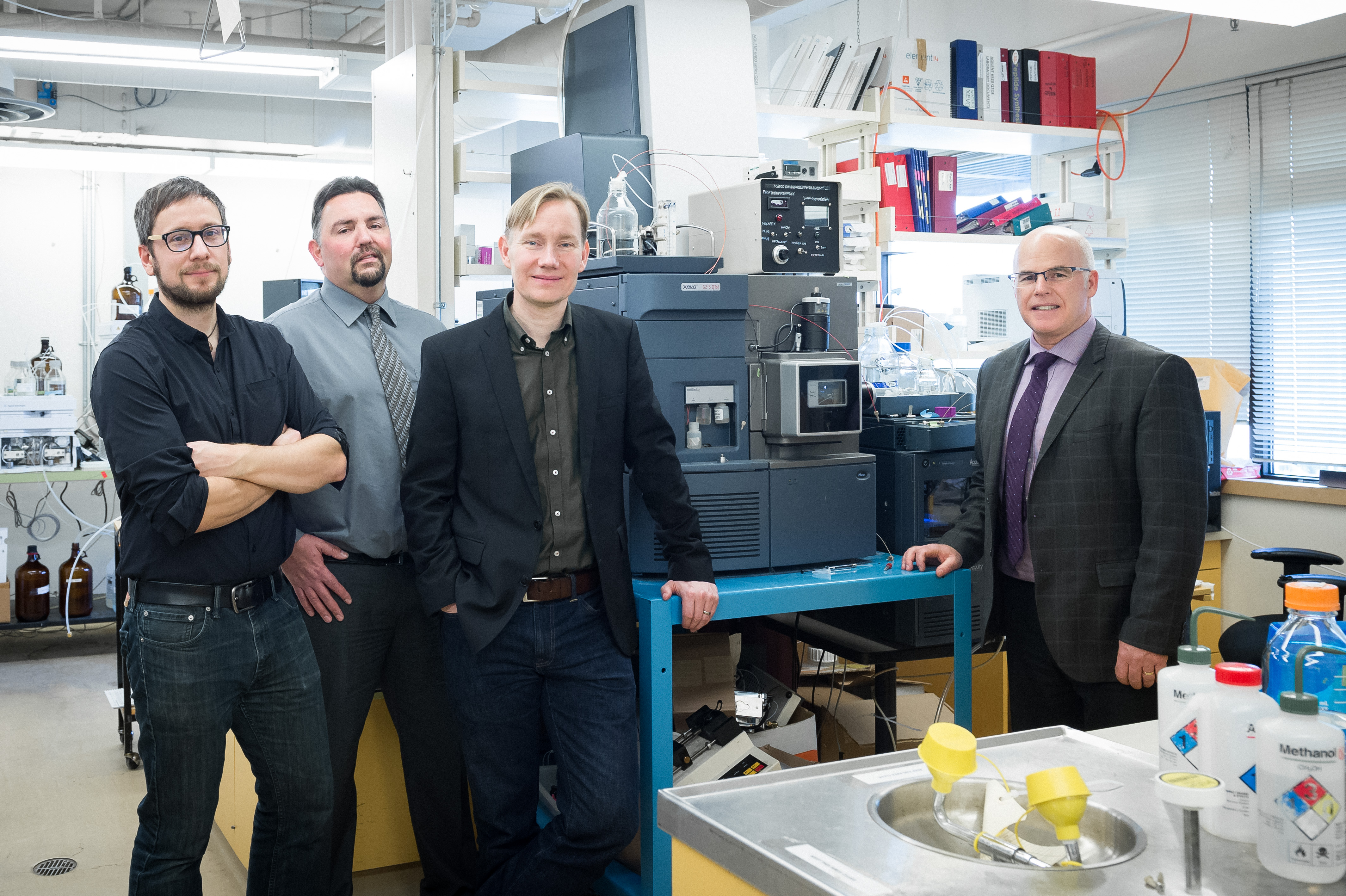

Harry Brumer’s focus is the development of better forest products. The UBC biochemist recently received funding from NSERC to support his enzyme genomic research, which will advance the development of new technology for cellulose-fibre modification. Brumer’s lab is also celebrating the arrival of new biomolecule analysis equipment provided by Waters Ltd.

Harry Brumer’s lab celebrates arrival of new biomolecule analyses equipment provided by Waters Ltd. Harry is pictured in the center. Source: Harry Brumer, UBC Science.

What kind of work goes on in your lab?

We use genomics and biochemical tools to study the natural diversity of enzymes and their functions, trying to map those which haven’t been explored. Enzymes are proteins with catalytic functions, which means they enhance chemical reactions. They are involved in the processes that build-up or break-down plant materials. Because plants are used in many ways by people, our research spans a range of activities from biomaterials development to understanding how gut bacteria help us digest dietary fibre.

Why is this important?

Breaking down or modifying plant biomass, to create biofuels, biochemicals, and biomaterials, are challenging. Plants have evolved to be very stable. Part of this stability arises from the tremendous complexity of the carbohydrates – polysaccharides – that make-up their cell walls. Figuring out which enzymes can surgically take apart certain components of plant cell walls expands our biotech “tool kit.” Having the right tools gives us the potential to develop products from renewable plant resources more cheaply and efficiently.

Can you tell me about some of the practical applications of your enzymology research?

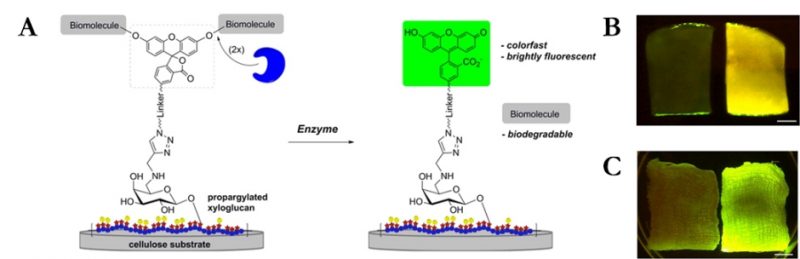

One of the projects we’ve been recently working on is the development of bioactive papers and other cellulose-based materials. Using direct visual indicators, such as fluorescence or colour changes, we can detect biomolecules including DNA and enzymes. These biosensors have application potential in many areas including smart packages to detect food spoilage, or advanced wound dressings to speed healing. Compared with synthetic materials, cellulose fibre-based devices are attractive because they are low cost, environmentally friendly, and beneficial in locations where resources are limited. Other enzyme technology we are developing can be used to create stronger materials at larger scales suitable for bulk products like packaging materials.

Visual detection of esterase activity on bioactive cellulose. (A) Surface tethering via the chromogen or fluorogen. (B) Visualization of esterase activity on bacterial cellulose pellicles. (C) Visualization of esterase activity on cotton gauze wound dressing containing clicked FTA dibutyrate.

Published in: Fatemeh Derikvand; DeLu Tyler Yin; Ryan Barrett; Harry Brumer; Anal. Chem. 2016, 88, 2989-2993. DOI: 10.1021/acs.analchem.5b04661

These biosensors have application potential in many areas including smart packages to detect food spoilage, or advanced wound dressings to speed healing.

Why is this type of research particularly important in British Columbia?

British Columbia has a strong forest sector. We want to make the most out of our abundant natural resources by making new, clever products, and finding ways to manufacture them more efficiently. Enzymology provides the tools to achieve this.